If you’re looking to personalize your denim jacket, or repair a tear in your favorite pair of jeans, or simply add an original letter embroidery patches design to your backpack patches are the ideal solution. They are practical and allow you to express yourself.

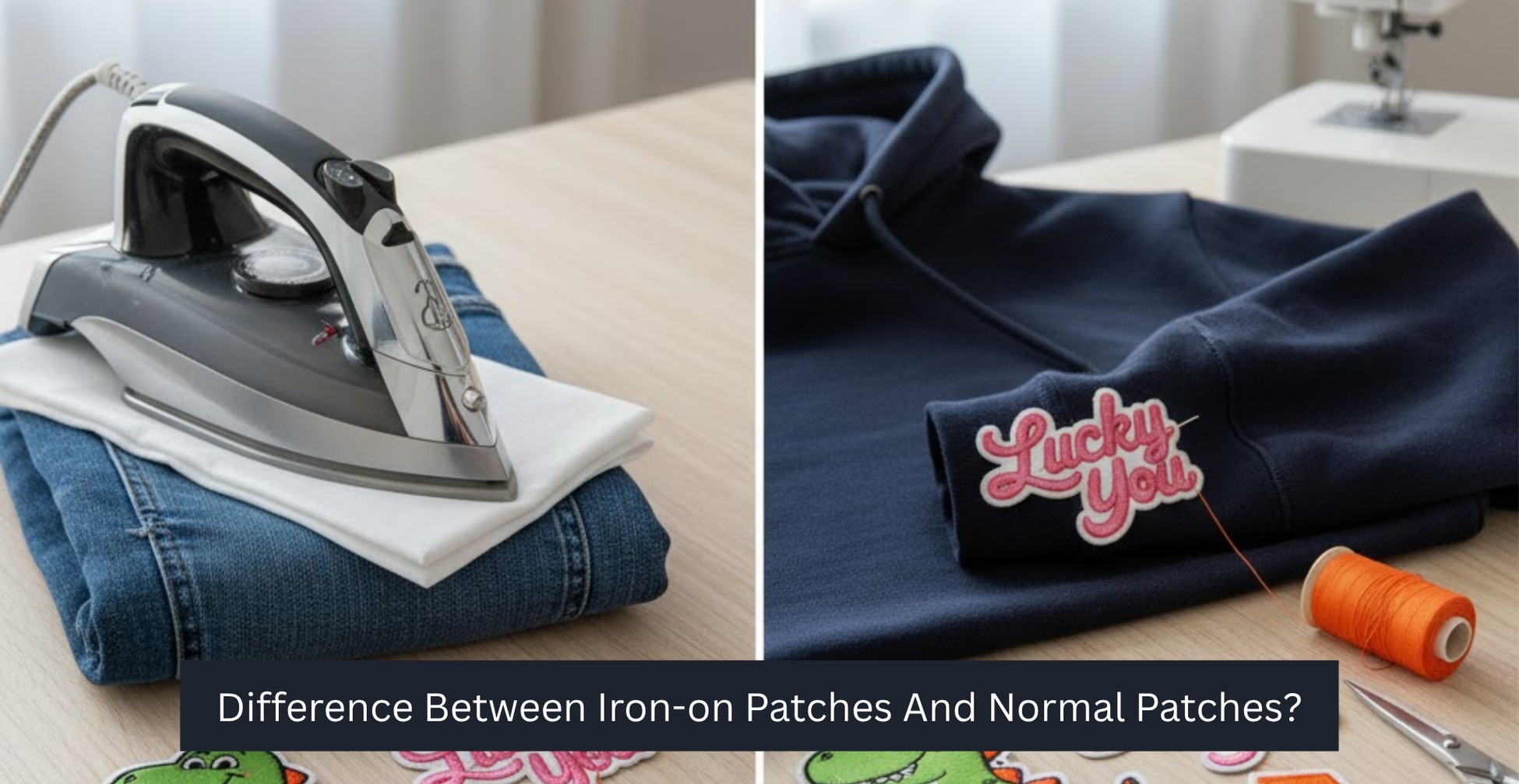

If you are looking for alternatives there is a common selection of patches suited to be quick and heat-activated (Iron-On Patches) as well as those that require thread and needle (Normal, or Sew-On Patches).

In SBS Digit, we transform digital images into perfect custom patches every day. We’re here to provide our expertise in order to guide you through the key distinctions between these two methods and ensure you select the most appropriate patch for longevity, fabric quality, and long-term fashion.

Defining the “Normal” Patch: The Sew-On Standard

If people are talking about “normal patches,” they are referring to “normal patch,” they are referring to traditional sew on clothes patches. These are the standard embroidered patches that do not come with a glue backing (or with an extremely thin, non-heat activated backing that is designed to be stable only).

Application and Durability

Sew-on patches are permanently secured by stitching them directly onto the fabric. This procedure requires a needle thread, time, and needle however it provides the highest degree of regarding security.

Applications: Manual sewing on patches is necessary. You can make use of a sewing machine (ideal for large patch jacket or patch pants projects) or you can hand sew them using a basic blanket or running stitch.

Security: This bonding is made of mechanical. The thread is used to anchor patches to fabric thereby making it immune to washing heavy, heat and constant friction. This is why many organizations sew on emblems or sew on badges on uniforms. They are designed to last.

Flexibility: Since no heat is required, sew on patches are able to be glued on nearly any fabric, even delicate fabrics like vinyl, leather, silk and even non-clothing items such as hats or bags in which the curvature makes heating difficult.

Understanding the Iron-On Patch

The main characteristic of iron on patches is the special adhesive glue that has been fused with its reverse. When the glue is exposed the extreme temperatures of an iron, it melts and forms an extremely strong bond to the fibers of the fabric being targeted.

Application and Limitations

The main benefit of an iron-on patch is its speed and simplicity. It’s the best option for quick fixes, like making use of iron-on patches for repair or adding a fashionable feature such as the lucky patch within minutes.

Applications: Quick and easy. Apply the patch over a clean cloth, then press it firmly using the hot iron. This removes the need for sewn patches in the first place.

Primary Use: Excellent for adding stability, or for fast clothes patches for holes, such as pants patches for holes on cotton or heavier synthetic materials. They are very well-liked in the craft market due to their simplicity.

Limitation: The adhesive bond will break in time, particularly after repeated washing or exposure to the extreme heat of drying. Crucially they are not able to be used on fabrics that are heat-sensitive (like rayon, nylon or even thin synthetic fabrics) without causing damaging the fabric.

The Critical Difference: Application Method

The differences between these two patch types are due completely to the way they’re applied, which determines their longevity and suitability for different types of clothing.

| Feature | Sew-On Patches (“Normal”) | Iron-On Patches |

| Backing | Plain backing or simple stabilizer | Film with adhesive that is heat-activated |

| Application | Machine or hand sewing patches | Pressure and heat that is high (Iron) |

| Durability | Permanent (Mechanical anchor) | Semi-Permanent (Adhesive bond) |

| Fabric Suitability | Ideal for All kinds of fabrics (leather, wool, nylon,) | The best choice for tough, heat-resistant fabrics (denim canvas, canvas, heavy cotton) |

| Time to Apply | The slower (requires stitching) | Faster (takes 30-60 minutes) |

Choosing the Right Patch for Your Project

As a supplier of customized embroidered patches iron, SBS Digit believes that the most appropriate option is based on the fabric as well as the purpose of use as well as your dedication to enduring.

1. For Durability and Longevity

If you’re designing something that is often washed like a patch’s hoodie or a uniform for work or putting decorative elements such as dinosaur patches to clothing for children make sure you choose the safety of sew on clothes patches. The mechanical stitching of the thread gives the best performance and durability.

2. For Quick Repair and Style

If you’re looking for a quick iron-on patch for clothing repair for a sturdy fabric such as a cotton tee or denim jacket using the iron-on method, it is suitable. It’s the best option if you want speed over long-lasting.

3. The Hybrid Approach: “Can You Sew on Iron on Patches?”

Yes, it is possible to can sew iron-on patches and this is usually the preferred method by professionals!

It combines the speed of the method using iron-on (which temporarily keeps the patch in place which makes it much simpler to work with) with the long-lasting nature of the stitch. This technique offers the most efficient of both and transforms a semi-permanent glue into a permanent one. The backing made of iron is an underlay, while the stitches create the mechanical lock.

Conclusion

The difference between the distinction between an iron-on patch and sew-in patch and an iron-on sew-in patch is not based on the quality of embroidery, it is all about the application method. While the iron-on method offers speed and ease of use however, the traditional sew-on technique (the “normal patch”) provides the unbeatable authority in terms of durability and compatibility with every fabric.

Pick the right patch according to the fabric you are using and purpose of use. To get the most reliable results, with wear-resistant properties especially for things with high stress like patches for pants always make sure to reinforce your patch with an extensive set with sewing patchwork.

Frequently Asked Questions (FAQs)

1. Are iron-on patches able to be easily removed?

Iron-on patches are intended to last for a long time; however, they are able to be removed with heat (like steam irons or hair dryer) and solvent (like adhesive remover or ruby alcohol). 5 The glue residue is difficult to get rid of completely without causing damage to the fabric.

2. What are the fabrics I should avoid applying iron-on patches to?

Beware of using iron-on patches on any synthetic or heat-sensitive material like spandex, nylon vinyl, leather rayon and 100 percent polyester. The intense heat needed is likely to melt or cause scorching of the materials.

3. Can you sew-on a patch to the most difficult materials like leather?

It is true that Sew-on patches for clothing is an only preferred method for materials like suede, leather or vinyl, since the adhesive of iron on patches won’t be able to properly bond and the heat could cause damage to the substance.

4. What can I do to ensure that my iron-on patches for repair last for longer?

To prolong the longevity of an iron-on patch strengthen the edges with an easy cycle of sewing on patches. Always wash the clothing inside out with cold water. Dry it in the air or tumble dry on a very low temperatures to keep the adhesive from deteriorating.

5. What is the meaning of ” iron sew” refers to?

The expression ” iron sew” or “iron-on, sew-on” typically refers to iron-embroidered patches iron with an adhesive backing, but is meant to be sewn for the longest time possible. It blends the convenience of temporary positioning and the safety in permanent sewing.