The success of every machine embroidery project depends on a tiny, yet often neglected instrument that is the embroidery needle. While top-quality stabilizers, threads and expert embroidery digitizing USA services are vital but a mismatched machine needle could result in continuous thread breakage, sloppy stitches and ruined fabric.

Here at SBS Digit We understand that understanding the needle is crucial to perfect stitching. This guide will take you through all the information you should know about needles starting with how to use needles to understanding the anatomy of an embroidery needle to ensuring it is perfectly matched to your thread and fabric.

The Critical Difference: Embroidery Needles vs Sewing Needles

A lot of beginners are wondering whether they could utilize a regular domestic sewing machine needle to make the embroidery machine. Technically, yes but it’s advised for work that is of high quality.

The primary distinction lies in two important areas the Eye and scarf.

- The eye: An embroidery needle has a bigger and more extended eye than a normal sewing needle. The large size was created to minimize friction and strain on the thread. This is especially true for the heavier special, metallic or threads used in machine embroidery. This is crucial in preventing the thread from breaking or shredding when it is subjected to the high-speed, repetitive movement in an embroidery machine.

- The scarf: It is an indentation on the back of the needle, above an eye. The Embroidery needles have a special scarf that permits the machine’s hook to rotate and move closer to the loop of thread. This reduces the risk of skipped stitches, that are an issue common to the common-purpose sewing machine. needle used for embroidery.

Making use of a high-quality embroidery machine needle is the easiest and cheapest method to enhance the quality of your stitches and minimize the number of frustrating mistakes.

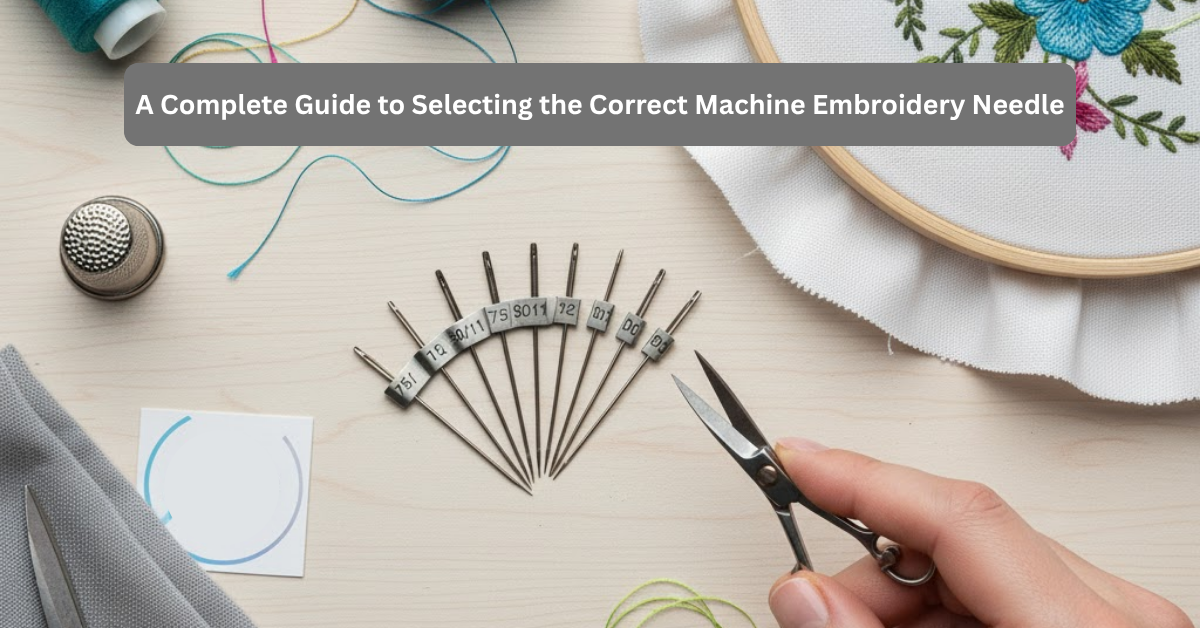

Needle Sizing Decoded: What Needle to Use for Embroidery

Embroidery needles are identified with a two-number coding system like 70/11, or even 90/14. The first number represents the European size in metric units (measuring its diameter as centimeters of millimeters) and the second number is that of the American dimension. 4 In both systems in both systems, a smaller number indicates a finer (thinner) needle.

The size of the thread and fabric is vital:

| Needle Size | Typical Fabric Application | Thread Weight | Key Benefit |

| 60/8 or 70/10 | Fine, delicate fabrics such as silk organza, sheer mesh. | 60wt or more refined | Small puncture hole. |

| 75/11 | Standard and is the most used to use machine embroidery. | 40wt (standard embroidery thread) | Great for cotton, twill and other medium-density patterns. |

| 80/12 | Medium-weight, slightly heavier fabrics, sturdy weaves. | 40wt or 30wt | Provides greater strength for light layering or for dense stitch areas. |

| 90/14 | Denim and other heavy-duty fabrics, such as canvas or thick towels. | 30wt or special/metallic threads. | Extra strength to punch through tough materials. |

Pro Tips from SBS Digit: For the majority of projects that require embroidery, the 75/11 embroidery needle when paired with a standard 40wt thread is the best choice. However, it is recommended to use heavier thread (like 30wt or metallic) or making use of a large object like a cap or jacket, make sure you increase the size to an 80/12 or a 90/14.

The Right Point for the Right Fabric

Above size, kind of point you have on the embroidery needle is crucial, since it will determine how the needle interacts the fibers of your fabric.

1. Sharp Point Needles

- Best for: Fabrics that are tightly woven canvas, denim, micro-fiber, and other layers of materials.

- The Reason: The sharp, precise needle effortlessly pierces fibers, creating a clear hole, preventing snagging and thread deflection. This is the ideal option for thick fabrics such as leather, or for needles for upholstery needle and thread application where a standard needle will be bent.

2. Ballpoint Needles

- Best for: Tee-shirts and knits and sportswear, fleece and any other stretchy fabric.

- The Reason: The rounded tip is able to push the fabric fibers away and does not cut it. This helps to prevent snags, runs and wear to the knit’s structure that can result in unsightly wrinkles or holes.

3. Metallic Needles

- Ideal for: Metal and special threads that are fragile.

- Why: These needles have been made with a large, highly polished eye that allows the thread to move through without friction, greatly reducing the possibility of shredding or breaking.

The SBS Digit Needle Checklist

Before beginning any task, you should go through this checklist to make sure you’ve chosen the right project:

- Material Weight: Materials that weigh less (silk and sheer) require delicate embroidery needles (60/8-75/11). Heavy fabric (denim and canvas) requires a more durable needle, bigger size (80/12-90/14).

- Fabric type: What is it? Is it knit or woven? Knits need a ballpoint; weavings usually require an incredibly strong or universal embroidery needle.

- Thread type: Threads that are thick or special (metallic or heavy cotton) require a larger needle eye (90/14) to avoid friction.

- Digitizing Quality: Even the correct needle will struggle with badly digitized files. Hi-quality embroidery digitizing USA guarantees that the density of stitches and pull compensation are both optimized for the fabric you are using and gives your needle the highest chances of success. SBS Digit specializes in enhancing designs for all types of fabrics.

When to Change Your Embroidery Needle

An eye needle which is blunt, bent or has a burr in the eye can cause discomfort regardless of its dimension or shape.

Change your needle if you notice any of these issues:

- Shredding or thread breakage frequently.

- Skipped stitches.

- Puckering or apparent cracks in the material.

- A thudding, dull sound that occurs during stitching.

In general, you should replace your embroidery needle at the end of 8-10 hours of stitching time or when you begin of a complex new task. It’s the least expensive way to protect yourself from costly errors!

Learning to use the appropriate machine embroidery needles is a crucial first step to achieving professional results. Rely on the experience from SBS Digit to get the perfect embroidery digitizing to fit your fabric, thread and most importantly, your choice of needle.